Expected Results

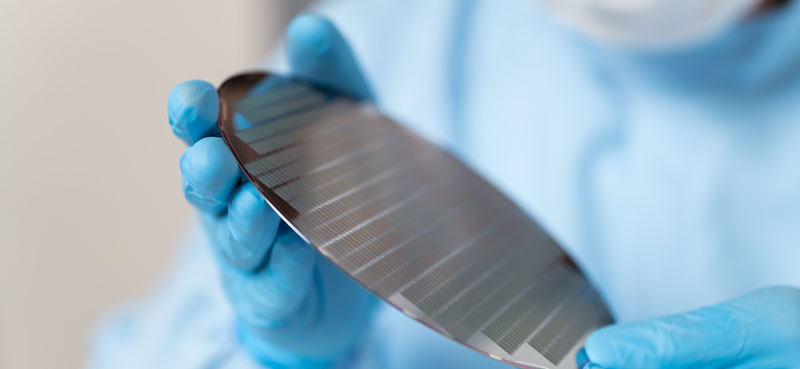

Laboratory-based characterisation of nanomaterials has been, and continues to be, one of the key enablers in the growth of knowledge and experience on nanotechnology and nano-enabled products. CHALLENGES will extend the scope of nano characterization beyond off-site laboratory based measurements to proper nanometrology, and is expected to have impacts on industrial production of nano-enabled materials and devices starting from the applications targeted within the project, but with impacts potentially able to be propagated to all major nanomanufacturing processes.

- Measurable improvement of speed by at least a factor 2 of nanoscale characterisation procedures, in comparison to already established performance and reliability for the application leading to a significant increase in industrial competitiveness.

- Significant reduction of the time and resources needed for nanomaterial development and upscaling, and for nanomaterials-based product development, which should be quantified with respect to established conditions for specific market sectors, with a return of investment in less than 5 years.

- Quantifiable enhancement of the ability to control the quality and reliability of products, with consequent improvement of product lifetime.

- Quantifiable enhancement of the ability to control the quality and reliability of products with associated environmental benefits.

CHALLENGES outputs and findings will increase Europe competitiveness in high-tech manufacturing industry, especially in markets where Asia and US have been dominating the scene, allowing to:

- Create a competitive edge in non-destructive technologies for materials characterization. Their implementation for in-line process inspection and control, will foster the competitiveness of EU Semiconductors, Photovoltaic and 2D Materials industries in global markets which are strongly dominated by the US and Asian industries;

- Give to EU industry a competitive edge in the production of nanotechnology enabled products, enabling more cost-effective production and quality control processes.