18 February 2022

CHALLENGES project kicked off on April 2020, exactly in the period when the COVID 19 outbreak was shutting down the world. Despite the difficulties which most of the world had to face to deal with the pandemic emergency, CHALLENGES partners made all their efforts to advance in the completion of the planned tasks.

In fact, each WP has been implemented, some first objectives have been achieved and many others are under development.

Thus, during these first 18 months, partners worked to get closer to the project goal: to obtain a family of multiscale real-time characterization technologies fully compatible with the manufacturing production lines.

To this aim, partners focused on developing cleanroom compliant tips (WP2) and instrumentation (WP3). In parallel, test materials were manufactured (WP1) and their characterization through established state-of-the-art techniques (WP4) was performed. Those phases are considered fundamental for the development of the project.

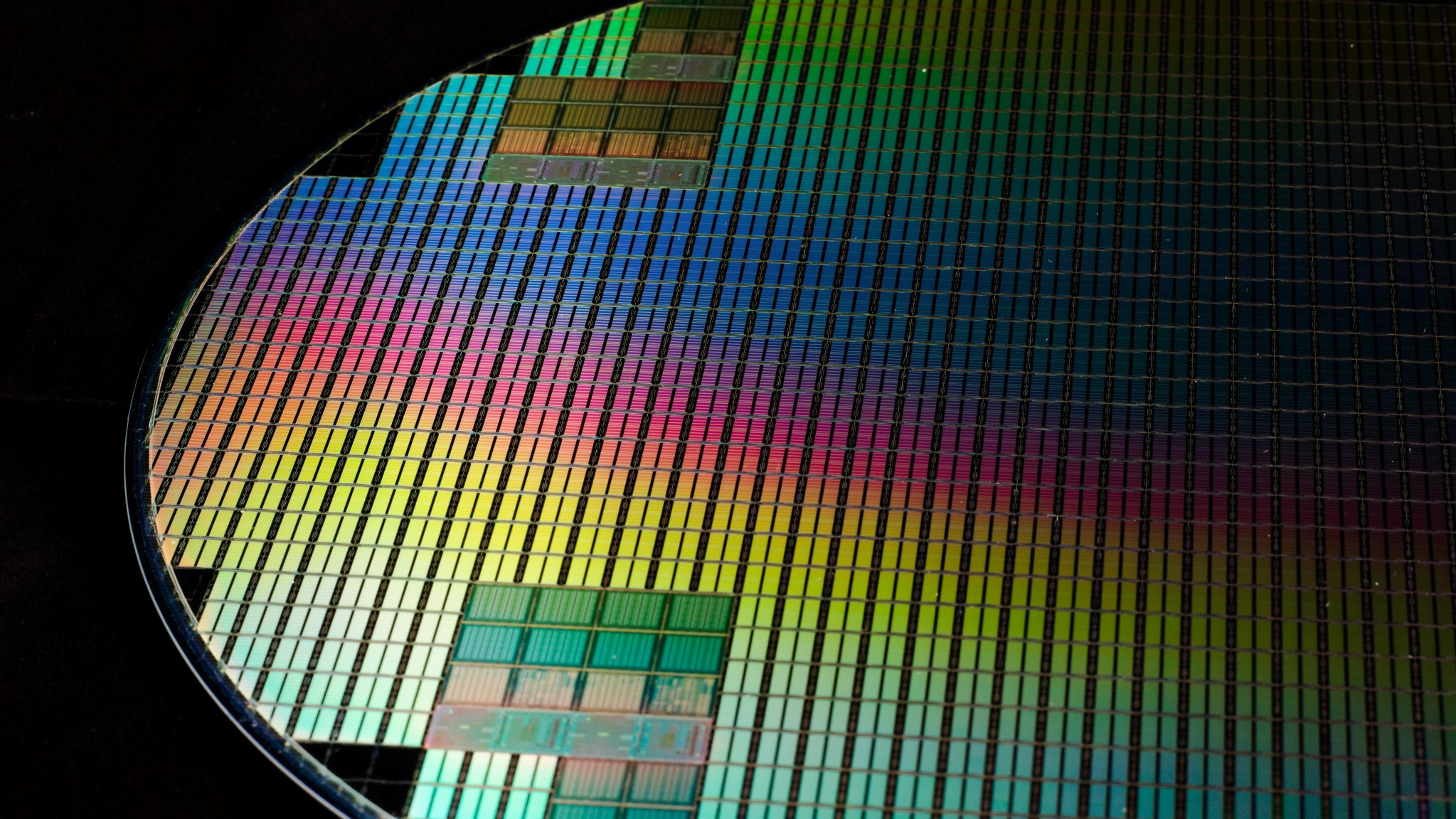

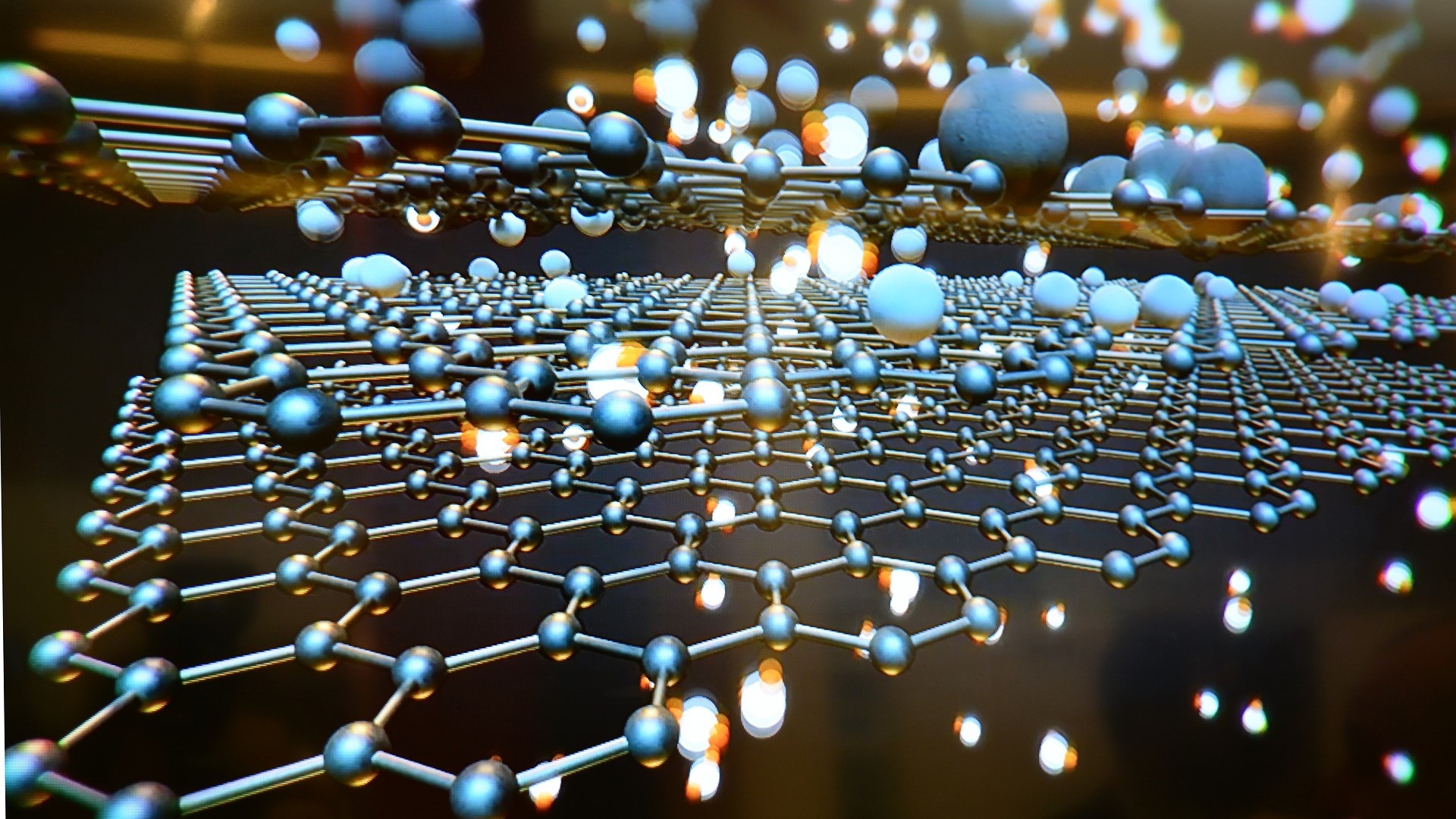

Specifically, three focus groups were established within the consortium to address the 3 application contexts of the project, namely semiconductor, photovoltaics, 2D materials.

All these activities are ongoing and will provide inputs for the next planned steps that will concern the benchmarking and validation of the newly developed tools compared to standard lab techniques (WP4).

This will be carried out in strong correlation with the definition of commonly agreed standard measurements protocols, metrology specifications, and data management protocols for all three applications contexts considered (WP5).

In the meanwhile, activities to prepare the path towards industrial scale-up after the end of the project are ongoing through sustainability and impacts assessments (WP6) and a continuous stakeholder involvement and networking (WP7).

Stay up to date with us and follow CHALLENGES project on social media!

Leave A Comment